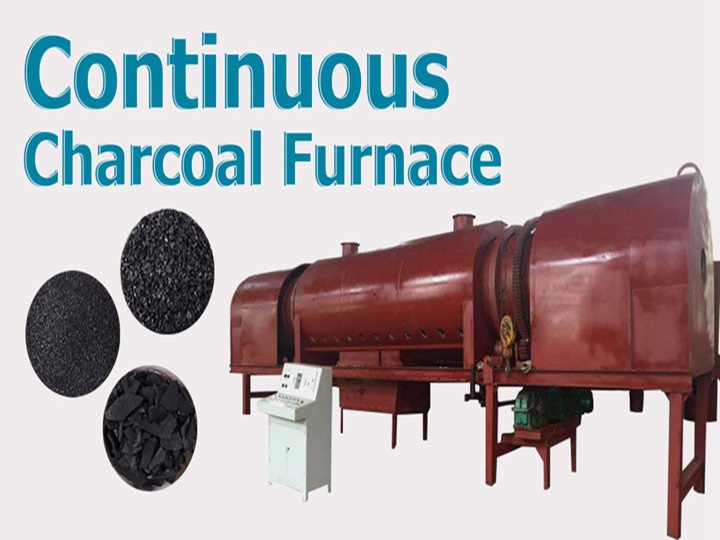

Continuous Charcoal Furnace for Biomass Charcoal Production

Continuous Carbonization Furnace | Charcoal Carbonizing Kiln

Continuous Charcoal Furnace for Biomass Charcoal Production

Continuous Carbonization Furnace | Charcoal Carbonizing Kiln

Features at a Glance

The continuous carbonization furnace is a new type of charcoal machine equipment. It is used for the mass production of rice husk charcoal and coconut shell charcoal. This industrial charcoal carbonizing furnace kiln is the upgrade of the traditional earth charcoal kiln in many Africa areas.

This continuous carbonization furnace can directly carbonize straw chips, rice husks, wood chips, sawdust, coconut shells, palm kernel shells, bamboo scraps, and other biomass materials. It has a difference from the hoist-type carbonization furnace and horizontal charcoal furnace.

With wide applications, it can also carbonize all kinds of wastes, such as paper mill wastes, wood factory wastes, plastic wastes, medical wastes, and municipal solid wastes.

This rotary coconut husk charcoal making machine is very popular among many African countries, Middle East, and Southeast Asian countries, such as Nigeria, Ghana, South Africa, Cameroon, Egypt, Guinea, Morocco, Sudan, Uganda, Saudi Arabia, Iraq, Jordan, Lebanon, Oman, Yemen, UAE, Philippines, Indonesia, Thailand, Malaysia, Cambodia, etc.

This continuous charcoal furnace is necessary equipment for various specifications of charcoal briquettes production lines and large-scale charcoal processing plants, such as hookah charcoal production lines, barbecue charcoal production lines, honeycomb coal production lines, etc. Charcoal carbonized by continuous carbonization furnace is also key equipment for industrial metallurgy, chemical, and pharmaceutical, soil improvement, deodorization operations, waste treatment, water purification, and household harmful gas removal.

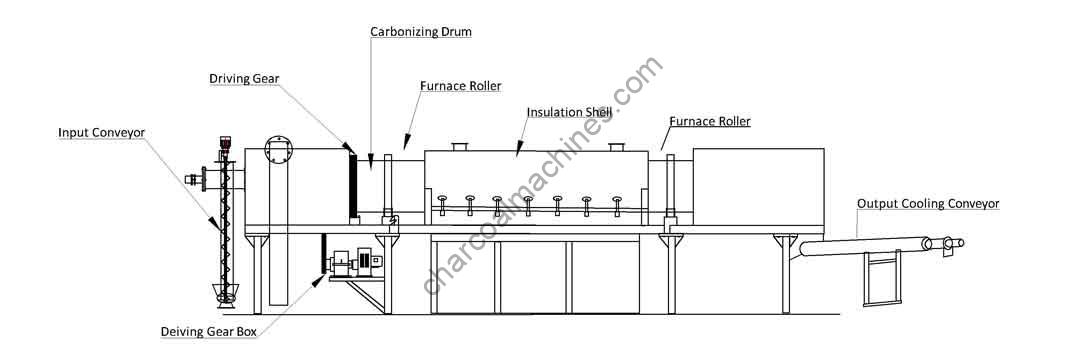

Structure of the continuous carbonization furnace

Continuous charcoal carbonization furnace is mainly composed of biomass gasifiers, flue gas purifiers, fan, self-matching gas burner, condensing device, etc.

This rice husk charcoal furnace can work continuously, and the raw material can enter from the inlet and output from the outlet continuously, which saves the cooling time and production time of charcoal.

In addition, this new design of rice husk charcoal machine can realize the recycling of combustible gas produced in the furnace, so it can save a lot of fuel consumption and labor costs.

In the process of operation, when the continuous carbonization furnace starts to heat up, a heat source is needed to heat the carbonization furnace.

One is to use the heat flow generated by the reverberatory furnace to heat the carbonization furnace to achieve the purpose of heating.

Charcoal furnace for making peanut shell charcoal video

How does the charcoal carbonizing kiln work?

The biomass is ignited through the gasifier, and the flue gas generated by the gasifier is recovered and purified, cooled into a combustible gas to burn in the carbonization machine.

When the biochar carbonization furnace is heated to a certain temperature, the raw materials in the carbonization furnace begin to carbonize, and the flue gas generated by carbonization is purified and cooled to become a combustible gas, which can be used as the carbonization heat source again.

Coking furnace after about 30 minutes, charcoal powder from the furnace into the cooling system for cooling, charcoal powder temperature rapidly by around 400 ℃ down to about 20-30 ℃, then charcoal powder can be exported and bagged.

Features of continuous carbonization machine

- The continuous charcoal furnace can work continuously, and the raw material can enter from the inlet and output from the outlet continuously, which saves the cooling time and production time of charcoal and has high production efficiency and large output.

- The continuity of carbonizing furnaces has realized char gasification, continuous carbonization, intelligent control, automatic collection of tar, wood vinegar liquid, and combustible gas cycle synchronization in a variety of functions. It has improved the product quality and has solved the problems of traditional carbonization having low efficiency, high labor intensity, and severe pollution problems realizing the reasonable utilization of renewable resources efficiently.

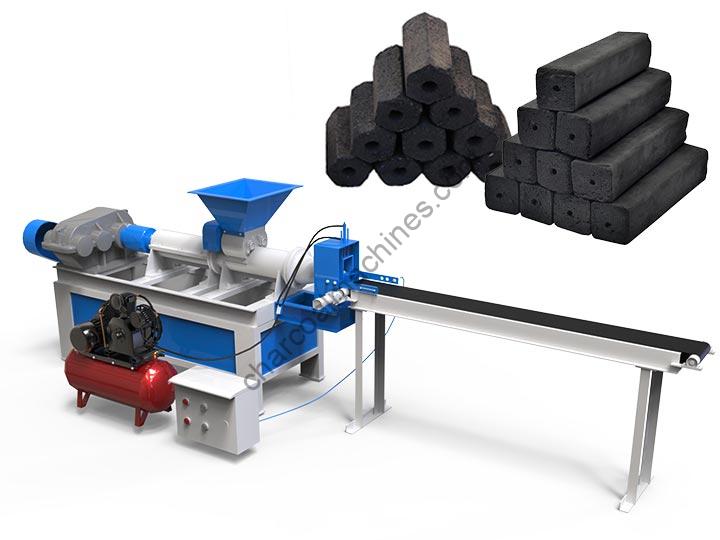

- The continuous carbonization furnace is mainly used in the charcoal production line of first carbonized and then molded. The carbonized charcoal is further crushed by the charcoal crusher and then enters the wheel grinding machine to mix in the binder for stirring. Then after the charcoal briquette machine is made into a finished charcoal bar.

Technical parameters of the continuous bio-charcoal furnace

| Model | SL-800 | SL-1000 | SL-1200 |

| Diameter(mm) | 800 | 1000 | 1200 |

| Capacity(kg/h) | 600-800 | 800-1000 | 1000-1200 |

| Main Power(kw) | 18.5 | 18.5 | 20 |

| Carbonization Temperature(℃) | 500-800 | 500-800 | 500-800 |

| Fan Power(kw) | 5.5 | 5.5 | 5.5 |

Hot sale market of Shuliy’s carbonization furnace

This new-designed continuous carbonizing furnace is in hot sale in Southeast Asian countries like Singapore, Indonesia, India, Vietnam, the Middle East countries like Saudi Arabia, Somalia, Iraq, Kuwait, and some Africa countries like Sudan, Morocco, Kenya and Uganda, and so on.

This charcoal machine has a wide usage for turning peanut shells, coconut shells, rice husk, sawdust, and other biomass wastes into high-quality charcoal.

The environment-friendly carbonization furnace is one kind of charcoal machine equipment that can carry on the continuous carbonization and the massive production of charcoal.

With large output, this continuous carbonizing furnace is widely used in the biomass charcoal production lines. It can be used with carbonization machine equipment, such as crusher, dryer, sawdust briquettes machine, to produce high-quality charcoal.

In addition, the furnace can directly and continuously carbonize raw materials, save carbonization time, improve carbonization efficiency and charcoal output.

The production capacity of the continuous carbonization furnace ranges from 300kg/h to 900kg/h. This continuous rice husk charcoal machine can bring you big profits that you can’t imagine.

How to make rice husk charcoal with the continuous charcoal machine?

Regular inspection for coconut shell charcoal carbonization furnace

Most of the charcoal producers, will not feel strange about the continuous carbonization furnaces. Because the continuous type carbonization furnace is widely used in charcoal production.

Almost all the agricultural and forestry wastes can be carbonized by this charcoal machine, like sawdust, rice husk, coconut shell, peanut shell, straw stems, and so on. Besides, can, tin foil, aluminum foil paper, and other materials can also be carbonized by the continuous carbonization furnace.

Although this coconut shell charcoal carbonizing machine is very practical, if there is no regular shutdown inspection and maintenance in the daily production, the machine’s working efficiency will be reduced and its service life will be affected. Therefore, it is necessary to take an eye on the good maintenance of the carbonization furnace.

How to maintain the continuous carbonizing furnace kiln?

In the charcoal production, according to the need, we sometimes to the charcoal furnace for a short period of downtime inspection and repair. Only regular maintenance and inspection can ensure the efficient operation of the machine and reduce the failure rate. The followings are some instructions for regular inspections of the carbonization furnace.

Short-term downtime check

After the machine is stopped, the whole machine is in a hot state. If the cylinder body is not often rotated, the Central Line of the cylinder body is prone to bending. A rotating cylinder is a very important and careful work to ensure that the centerline does not bend.

To this end, it is recommended that: In the first half-hour after the stop, turn the cylinder body 1/4 turn every 1-5 minutes; In the first hour after a stop, turn the cylinder body 1/4 turn every 5-10 minutes.

Long-term shutdown and inspection

- After the machine stops, rotate the cylinder body periodically according to the above provisions until it is completely cooled.

- Inspection after shutdown: check all connection bolts for looseness and damage, especially those with the large ring gear. Whether there are cracks in the welds of the cylinder and the backing plate. Whether the lubricating oil at each lubrication point needs to be replaced, cleaned, or supplemented. If it needs to be replaced, the remaining oil should be drained, cleaned, and refilled with new oil.

Lubrication and cooling

Another important work to maintain the continuous carbonizing machine is to give good lubrication to the moving parts of this charcoal machine, to extend the service life of the parts, and reduce the repair costs.

Coconut shell charcoal carbonization furnace video

Lubrication of the charcoal carbonizing machine

- The lubricating oil and grease shall be used correctly. The substitute product must meet the specified grease performance requirements, and only the oil with high viscosity can replace the oil with low viscosity.

- Check the oil level once per shift. If the oil level is lowered to the lower limit of the oil level indicator scale, it must be immediately filled to the upper limit of the oil level indicator.

- After a long-term stop, before starting, the oil must be poured on the roller sliding bearing with the oil pot, and then start.

In addition, it is important to note that the maintenance workers should pay attention to the roller bearings of the cooling system. The surface of the roller is cooled by water flowing from the roller seat.

The height of the water surface of the water tank can be controlled by turning the PVC pipe. When the downtime is longer or in winter stops, we should release all the cooling water, to avoid freezing caused by pipe expansion crack.

How to deeply process the coconut charcoal from the continuous charcoal furnace?

We can grind coconut shell charcoal, bamboo chip charcoal, wood chip charcoal, rice husk charcoal, etc. into fine charcoal powder by using a charcoal grinder and Raymond mill, which are used to process various briquette charcoal products of different specifications.

Charcoal powder extruding and briquetting

Use charcoal briquettes extruder machine to process charcoal briquettes in a quadrangular or hexagonal prism shape.

Use different types of hookah charcoal press machines to make square and round hookah charcoals. The size, pattern, and shape of hookah charcoal can be customized.

The barbecue charcoal press machine can be used to squeeze the charcoal powder into spherical, oval, or pillow-shaped barbecue charcoal briquettes.

This new type of compressed charcoal making machine can squeeze charcoal powder or coal powder into honeycomb or charcoal bricks.

Customer cases of this continuous charcoal carbonizing machine

1000kg/h Carbonization Furnace Plant Was Shipped to Congo

Coconut shell charcoal making machine successfully installed and put into production in Thailand

Welcome India customers visit Shuliy charcoal making machine factory!

Malaysia Charcoal Plant Feedback video

1t/h continuous carbonization furnace shipped to the UK

Hot Product

Comprehensive Pallet Crusher for Shredding Wood Wastes

The comprehensive pallet crusher, namely the scrap wood…

Barbecue Charcoal Production Line | BBQ Briquettes Processing Plant

The barbecue charcoal production line mainly processes various…

Charcoal Grinder Machine for Making Fine Charcoal Powder

The lump charcoal grinder machine also known as…

Wood Pellet Machine for Making Biomass Pellet Fuel

Wood pellet machine refers to the compression of…

Wood Debarker Machine for Peeling Logs

Wood debarker machine, also known as the log…

Charcoal Briquettes Packaging Machine for Packing Barbecue Charcoal Quantitatively

This quantitative charcoal briquettes packaging machine can be…

Shisha (Hookah) Charcoal Production Line | Briquette Packaging Dryer Plant

The automatic shisha(hookah) charcoal production line is the…

Charcoal Coal Briquettes Extruder Machine for Charcoal Plant

Charcoal briquette machine can extrude charcoal & coal…

Honeycomb Coal Briquette Production Line | Briquettes Charcoal Processing Plant

The honeycomb coal briquette production line can turn…

8 comments